A toothbrush is an instrument used to clean teeth to prevent cavities and gingivitis or gum disease leading to bad breath and tooth loss. Made with bristles and a handle, the toothbrush needs toothpaste to clean more effectively on the teeth and along the gum line. It has been considered an important part of daily oral hygiene.

The toothbrush similar to what we use today was invented in 1938. But as early as 3000 BC, early forms of toothbrushes had been invented. Ancient civilization’s toothbrushes are made of thin twigs. They are called ‘chew sticks’ where one end is frayed and rubbed against each tooth. The frayed end cleans in between teeth. These were invented by the Egyptians and were also done by Greeks, Romans, and Indians.

In 1498, the first natural bristle toothbrush that is similar to what we used to today, was invented in China. Coarse hairs from the back of the hog’s neck were taken to form its bristles, while bone or bamboo was used to make the handle. The bristles were stiff until boar bristles were used in 1938.

The 15th-century creation of toothbrushes was still followed by toothbrushes fashioned out of silver in the English nobility a century after. In early 1900, Siberian hog hair was used for toothbrush bristles. Toothbrushes’ design has gone through significant changes in history. But 1938 marks the revolution of toothbrushes where the soft-bristled were invented. It is the year that the first nylon bristles were introduced. When the Americans were impressed by the disciplined oral hygiene habits of the soldiers coming back home after World War II, they became progressively concerned about practicing good oral health care. They adopted the use of nylon bristles. The first electric toothbrush that hit the American market was in 1960 but the first electric toothbrush was invented in 1939.

Toothbrushes have gone through a few substantial changes. In the late 1970s, after the mass production of toothbrushes all around the world, the toothbrush industry began mixing out a range of new designs. These variations are in bristle shape, size, and texture, as well as non-traditional handle styles.

Countless styles of toothbrushes occupied the market stating their power over brands. But generally, the manufacturing of toothbrushes is done mechanically. Since they are consist of plastic handles and nylon bristles, they undergo the following process:

- Molding the handles

Plastic pellets are placed in an injection molding machine. It heats the plastic until it is melted. A rotating screw forces the liquid into the molds forming the entire toothbrush handle and the cores, where bristles are inserted. Once adequately cooled, the clamps are removed with the small pins that push the handles out of the molds. The size, shape, and design of the handle vary depending on the intended user.

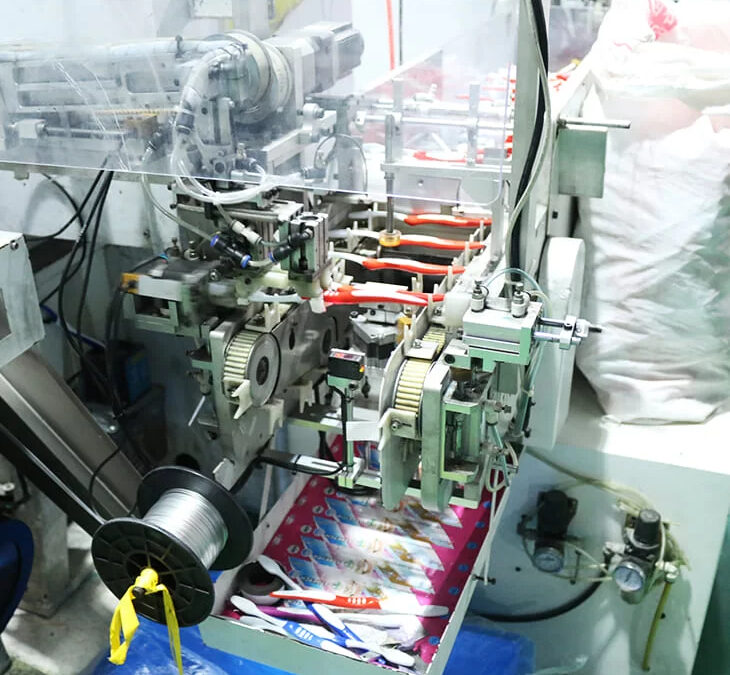

- Stapling the bristles

With the use of a filling machine, automatically, the bristles are positioned into the core. The nylon bristles are generally employed. Tiny metal staples are used to fix the bristles into the core.

- Trimming the bristles

A trimming machine is used for bristles to have an equal length or a particular design. Bristles can be of equal length flat design or with multiple layers, which is the zigzag design.

- Packaging the toothbrushes

Toothbrushes are packaged using cardboard, plastics, or a combination of both. The labels whether hard or soft bristles are placed including the recommendations for usage.

Plastic toothbrushes with astonishing designs came out. They have coated bristles. The blue coat on the tip of the bristles would fade to white. Other brands featured taller contoured bristles that massage the gums. There are also flexible, angled handles that reduce pressure on teeth and gums.

As the mass production of plastic toothbrushes has raised the concern of the environmentally concerned communities, they promote the use of natural toothbrushes and bring them back to the market. Natural toothbrushes are made up of bamboo handles. They have either nylon or natural bristles from the hair of the boar. A different process is made in the manufacturing of these natural toothbrushes. A bamboo undergoes the following several processes before it is used and shaped like a toothbrush handle:

- Preparing the bamboo

The bamboo is harvested and cut into lengths, such as 120 cm, 160 cm, and 200 cm. They will split the canes into pieces. Next, they will smoothen the surface and carbonize the bamboo into high temperatures. This process sterilizes impurities. Then, they evaporate the sugar and wait till the bamboo becomes darker. They are ready to dry.

- Shaping the bamboo

In this process, they will cut the bamboo into toothbrush length. Then, they will use a machine to finish the side, the front, and the back. They will polish them and create holes for the bristles after.

- Tufting the bristles

Through pressure, soft or hard bristles are tufted on the bamboo. Bristles are placed without the use of glue.

- Engraving name and logo on the handle

For branding and customization purposes, they engrave the name of the company, logo, or name of the user on the toothbrush handle.

- Packaging the bamboo toothbrush

Recycled paper boxes or pouches are used in the packaging of bamboo toothbrushes. Labels such as ‘soft bristles,’ ‘with natural antibacterial properties,’ ‘BPA-free,’ and ‘biodegradable’ are present in the box.

Electric toothbrushes are invented for people with limited mobility and people under orthodontic therapy to prevent plaque builds up and gum disease. These make brushing easier and faster. The following are the steps in making an electric toothbrush:

- Designing the handle

The design of the handle varies. It depends on whether the user is a child or an adult. This includes creating molds. The handle is larger and hollow for a motor and battery to be fitted within.

- Molding the brush head

A similar process of creating plastic toothbrushes is employed. Plastic pellets are taken to an injection molding machine.

- Entering the filling machine.

Bristles are positioned to the core

- Trimming the bristles

Once the bristles are in place, they are cut and shaped with the computer-guided machine.

- Sterilizing the brush

The brush heads pass through UV light to kill bacteria.

- Inserting the motor, gearing system, and battery

This is the process where the motor, gearing system, and battery are inserted and connected. If they are functioning perfectly, they are sealed inside a hollow brush handle casing with plastic.

- Packaging the electric toothbrushes

They are placed in a larger box with the right brush head and other accessories. The box has all information about the product.

Whatever toothbrush you choose, it undergoes quality control to guarantee that product’s efficiency. Meanwhile, manufacturers never stop the recreation of excellent toothbrushes for your oral health’s comfort and safety.